Operation of the Wimshurst machine

The Wimshurst

machine is an "influence machine", an electrostatic generator that uses

the charges already present on it to generate more charges by

electrostatic induction. It does not rely on friction for its operation.

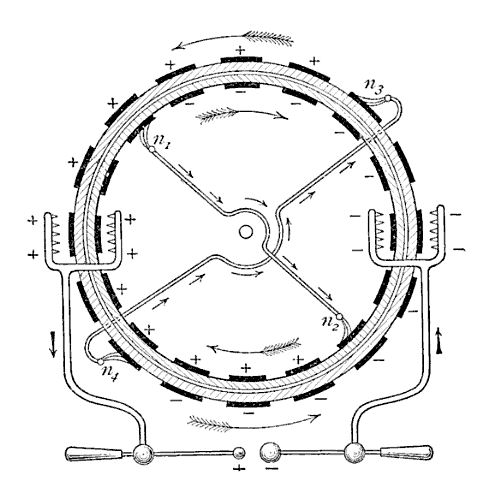

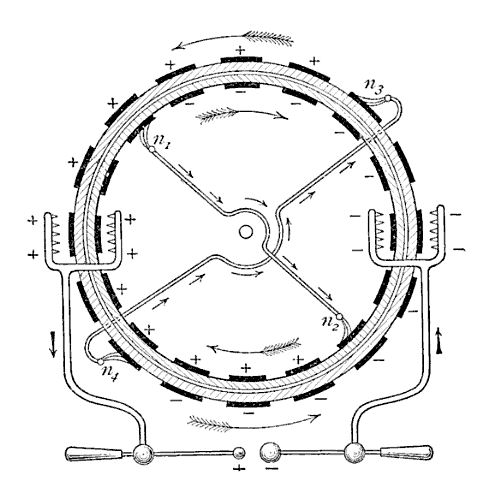

Consider that the machine is charged as in the schematic representation,

shown (with cylinders instead of disks) with each half of each disk with

one polarity, with boundaries at the neutralizing bars. Ignore the charge

collectors and the output circuit. The two neutralizer bars are shown

floating, but it makes no difference in the operation if they are

grounded. At top and bottom, the charges are opposite, and at the sides

equal. With any small initial charge unbalance, the machine will quickly

fall into this configuration. After this occurs, when a sector touches a

neutralizing brush charge is attracted to it, with polarity opposite to

the charges at the other disk, due to the influence of the electric field

generated by the surrounding sectors. Since there are several sectors

inducing charge in just one sector, more charge than is present in each of

the opposite sectors is attracted, provided that the disks and sectors are

at sufficiently small distance. The effect is that progressively larger

charges are attracted to the neutralized sectors as the disks turn, and

the voltages at all fixed sector positions grow exponentially. The buildup

stops when the charge density on the sector surfaces creates an electric

field intense enough to cause breakdown in the air around, usually just

before they reach the neutralizing brushes. The machine then operates

generating a constant current at the output circuit, with maximum voltage

limited by sparking through the path formed by a series of sectors and a

neutralizer rod, or by other losses in the structure due to insufficient

insulation. Note that the induction from the adjacent sectors in the same

disk is important. The sectors before a sector touching a neutralizer, and

also the charge collector assemblies and sectors at the sides of the

disks, generate intense electric field, and help in the induction. The

sectors ahead have their prejudicial effect reduced by the oppositely

charged sectors in the other disk. The machine is self-starting,

because there is always some natural imbalance in the charges. The use of

different metals in the sectors and in the neutralizing brushes helps the

startup process due to contact potential developed when different metals

touch.

The Wimshurst

machine is an "influence machine", an electrostatic generator that uses

the charges already present on it to generate more charges by

electrostatic induction. It does not rely on friction for its operation.

Consider that the machine is charged as in the schematic representation,

shown (with cylinders instead of disks) with each half of each disk with

one polarity, with boundaries at the neutralizing bars. Ignore the charge

collectors and the output circuit. The two neutralizer bars are shown

floating, but it makes no difference in the operation if they are

grounded. At top and bottom, the charges are opposite, and at the sides

equal. With any small initial charge unbalance, the machine will quickly

fall into this configuration. After this occurs, when a sector touches a

neutralizing brush charge is attracted to it, with polarity opposite to

the charges at the other disk, due to the influence of the electric field

generated by the surrounding sectors. Since there are several sectors

inducing charge in just one sector, more charge than is present in each of

the opposite sectors is attracted, provided that the disks and sectors are

at sufficiently small distance. The effect is that progressively larger

charges are attracted to the neutralized sectors as the disks turn, and

the voltages at all fixed sector positions grow exponentially. The buildup

stops when the charge density on the sector surfaces creates an electric

field intense enough to cause breakdown in the air around, usually just

before they reach the neutralizing brushes. The machine then operates

generating a constant current at the output circuit, with maximum voltage

limited by sparking through the path formed by a series of sectors and a

neutralizer rod, or by other losses in the structure due to insufficient

insulation. Note that the induction from the adjacent sectors in the same

disk is important. The sectors before a sector touching a neutralizer, and

also the charge collector assemblies and sectors at the sides of the

disks, generate intense electric field, and help in the induction. The

sectors ahead have their prejudicial effect reduced by the oppositely

charged sectors in the other disk. The machine is self-starting,

because there is always some natural imbalance in the charges. The use of

different metals in the sectors and in the neutralizing brushes helps the

startup process due to contact potential developed when different metals

touch.

The machine still works with just one disk

turning, if the other is stopped and kept charged in some way. This idea

is the base of the older machines of Holtz, Voss, and others, that use a rotating disk and a

fixed disk with inductor plates. The elegant design of the Wimshurst

machine uses the same disks to generate new charges and to induce charges,

and keeps all the parts of the disks alternating polarity twice at each

turn. This is important to avoid charge buildup at the unused sides of the

disks, what in the machines with fixed inductors eventually reduce the

induction effect and may cause periodical polarity reversals. The top and

bottom of the machine operate at relatively low voltages, due to the

opposite charges in the disk sectors at opposite sides. This reduces

losses to the supporting structure and allows the upright supports, belts

and pulleys to be positioned much closer to the disks than in other

machines. At the sides of the machine, the disk sectors are charged with

equal polarities, and far from the influence of the other side of the

machine. A very high voltage appears, because the same charges generated

at the top and bottom of the disks, where there is significant capacitance

between oppositely charged sectors, are now widely separated, with low

capacitance between them.

Collectors with metal points extract some

charge to the machine terminals, that are so charged to the same voltage.

A Faraday cage effect helps in the discharge of the sectors to the charge

collectors. If the terminals are kept too far apart, eventually a spark

will jump across the sectors in one of the disks and a neutralizing bar,

discharging the machine. The maximum spark length is so approximately the

sum of the sector spacings across a third of a disk (assuming the

neutralizers at 60 degrees with the horizontal). Somewhat larger, because

less voltage is necessary to cause a large spark than to cause a series of

smaller sparks adding to the same length. The reason is that the sectors

distribute the electric field more uniformly across the gap, reducing its

maximum value. Due to this, the machine works better with many sectors

than with few. 32 or 40 sectors are the usual, but 16 or 24 are enough for

reasonable performance. The minimum is 8, maybe 6. Of course the shape of

the terminals affects the maximum spark length, but the rule above works

very well in the prediction of the maximum that can be obtained.

The maximum output current of a Wimshurst

machine depends essentially on the area occupied by the sectors in the

disks and on the rotation speed. See how. In

steady state, the machine acts as a current source for a load connected to

its terminals, including losses by internal corona and sparking.

Curiously, practically just one disk contributes to the output

current, because if the charge of one sector is removed by a charge

collector, the potential at the corresponding sector in the other disk

decreases due to the relatively high capacitance between the disks, and

the potential difference between this sector and the charge collector

becomes too small for a discharge across the air interval separating them.

It is possible to collect charge from just one disk instead of from both

disks. The obtained current is a good fraction of the regular output due

to the same effect. It is even possible to eliminate the neutralizer from

the side where current is taken, with the output circuit serving as

neutralizer, but in this case the machine is less reliable, requiring a

short-circuit at the output for startup and stops easily. There is a way

to extract charge of both disks, due to Schaffers

[p29].

The charge collectors are displaced in the direction of the adjacent

neutralizers. This avoids the reduction of the potential at the sectors in

the other disk, and ideally doubles the output current of the machine. The

spark length is somewhat reduced, due to the smaller distance between

charge collectors and neutralizers.

Bright sparks require intense current. The

current can be obtained by storing the charge extracted from the rotating

discs in high-voltage capacitors (Leyden jars) connected across the

machine terminals. The classical design comprises two Leyden jars with the

insulated terminals connected one to each terminal, and the outer

terminals interconnected. The spark gap usually consists of two metallic

balls connected by metal bars to the charge collectors. Significantly

longer sparks can be obtained by the addition of a smaller ball attached

to the positive terminal. This increases the electric field around the

positive terminal, forcing the ionization of the air to start at the

positive side of the gap, instead of at the negative side, as happens with

a symmetrical gap. The positive ionization forms a nice plume-like

structure (that can be seen in the dark) pointing away from the positive

terminal, that easily gets connected to the diffuse corona that the

negative terminal emits. When the connection is established, a spark

occurs, with the electrons flowing from the negative terminal to the

positive. Short sparks are observed as bright straight lines. Longer

sparks are more irregular, and may present branches, almost always in the

direction of the negative terminal. In short sparks, the positive end is

brighter, specially in sparks obtained without added Leyden jars, due to

more concentrated current. In long sparks, the positive end is always a

straight line perpendicular to the surface of the terminal, with the

negative side irregular and a little brighter (why is a mystery). When the

terminals are close to the maximum separation, "failed" sparks frequently

occur. The charges that the spark formation drains from the terminals

reduce the voltage between the terminals, and the spark is dissipated

before completion. Larger capacitance in the Leyden jars can extend

somewhat the maximum spark length, by providing more charge to complete

sparks that would "fail". The addition of a smaller ball to the negative

terminal is not effective. The electrons are ejected by the intense

electric field, and disperse quickly through the air instead of forming an

ionized path. This can be observed by a characteristic hissing noise. The

smaller ball doesn't need to be electrically connected to the main

positive terminal. It is still more effective if separated from the larger

ball by a short length of insulator (a short plastic tube, for example).

The small sparks between the larger ball and the smaller ball apparently

increase the ionization around the terminal, and the separation reduces

the loss of charge to the air (this I observed in my machines). In any

case, the longest sparks are obtained with the neutralizers at high angle.

Low angles increase the output current a bit [35].

Small balls can be added to both terminals, and in this case the longest

sparks are obtained with the positive terminal inclined

in the direction of the negative [35]. Another interesting gap structure

is the ball-plane gap, that replaces the

negative ball by a disk with rounded edges. This kind of gap requires less

voltage to produce a spark, and can produce very long sparks.

The terminal balls shall correspond to the

capabilities of the machine. A symmetrical gap with two spheres produces

sparks with up to about 4 times the diameter of the spheres. A ball-plane

gap goes to about 8 times the diameter of the sphere. Assuming that the

maximum spark length is approximately the sum of the distances between

adjacent sectors across a third of a disk, D,

the balls can be dimensioned based on this, with balls with diameter D/4 for a symmetrical gap and D/8 for a ball-plane gap. A double

ball gap can use this two sizes, maybe with the large ball larger. If the

small ball is insulated from the large ball, it can be even smaller than D/8.

The schematic above is from [68].

Simulations

The operation of the machine can be analyzed

quantitatively with the help of an electrostatic simulator. The simulation

result below shows an idealized section of the disks, with

three sectors in each disk, with the central sector e

touching a neutralizer brush. The simulated sectors are rectangular plates

with rounded surfaces, with 5 cm in length (direction perpendicular to the

plane), width of 1.5 cm and spacing of 1.5 cm. The disk plates have a

relative permittivity of 4, 0.25 cm of thickness and 0.5 cm of spacing.

The sectors a, b,

c, and d

are initialized with a total charge of +10 nC in each. The sector e

is grounded to 0 V (by a neutralizer brush), and sector f

, having already passed under the neutralizing brush, has a charge

identical to the charge in sector e.

A series of simulations is performed with the charge in sector f

varied until this condition is met. The simulation calculates the voltages

at the sectors as Va = 11 kV, Vb = 5.9 kV, Vc

= 3.0 kV, Vd = 11 kV, Ve

= 0 V, and V f= -3 kV. The

charge in sector e is found as

-14 nC. The arrows showing the directions and relative intensity of the

electric field show clearly that sector e

is influenced by sectors a, b, and d,

and this multiple influence is the cause of the charge gain of -1.4.

The machine can also be considered as a

network of variable capacitors and switches, with capacitances from the

sectors to ground and between all the pairs of sectors. The capacitances

between sector pairs in the same disk are significant only between

adjacent sectors. The capacitances between pairs of sectors in opposite

disks vary periodically in the time taken for a turn, becoming large when

they are facing each other and decreasing to practically zero when they

are at two sectors or more of angular distance. The other

capacitances, from sectors to ground and between adjacent sectors in a

disk, vary too, but in a first approximation they can be considered fixed.

The sectors are grounded periodically, in correspondence with the times

when they touch the neutralizers, twice per turn. The output circuit adds

another set of switches, connecting the sectors to the output at proper

times. This circuit model can be simulated in standard circuit simulators.

The picture below shows the result of a simulation of the startup of a

Wimshurst machine with 16 sectors per disk, turning at 10 turn/second. The

sectors are assumed to have 1 pF of capacitance to ground, 0.5 pF to

adjacent sectors, 5 pF to the opposite sector, and 2.5 pF to adjacent

sectors in the other disk. The voltages at three adjacent sectors and at

the two 100-pF Leyden jars can be seen. The initial excitation was

provided by ±10 V initially in the Leyden jars. In just three turns the

Leyden jars reach ±184 V.

Antonio C. M. de Queiroz

Created: 1996

Last update: 19 February 2018

Return to Electrostatic Machines

The Wimshurst

machine is an "influence machine", an electrostatic generator that uses

the charges already present on it to generate more charges by

electrostatic induction. It does not rely on friction for its operation.

Consider that the machine is charged as in the schematic representation,

shown (with cylinders instead of disks) with each half of each disk with

one polarity, with boundaries at the neutralizing bars. Ignore the charge

collectors and the output circuit. The two neutralizer bars are shown

floating, but it makes no difference in the operation if they are

grounded. At top and bottom, the charges are opposite, and at the sides

equal. With any small initial charge unbalance, the machine will quickly

fall into this configuration. After this occurs, when a sector touches a

neutralizing brush charge is attracted to it, with polarity opposite to

the charges at the other disk, due to the influence of the electric field

generated by the surrounding sectors. Since there are several sectors

inducing charge in just one sector, more charge than is present in each of

the opposite sectors is attracted, provided that the disks and sectors are

at sufficiently small distance. The effect is that progressively larger

charges are attracted to the neutralized sectors as the disks turn, and

the voltages at all fixed sector positions grow exponentially. The buildup

stops when the charge density on the sector surfaces creates an electric

field intense enough to cause breakdown in the air around, usually just

before they reach the neutralizing brushes. The machine then operates

generating a constant current at the output circuit, with maximum voltage

limited by sparking through the path formed by a series of sectors and a

neutralizer rod, or by other losses in the structure due to insufficient

insulation. Note that the induction from the adjacent sectors in the same

disk is important. The sectors before a sector touching a neutralizer, and

also the charge collector assemblies and sectors at the sides of the

disks, generate intense electric field, and help in the induction. The

sectors ahead have their prejudicial effect reduced by the oppositely

charged sectors in the other disk. The machine is self-starting,

because there is always some natural imbalance in the charges. The use of

different metals in the sectors and in the neutralizing brushes helps the

startup process due to contact potential developed when different metals

touch.

The Wimshurst

machine is an "influence machine", an electrostatic generator that uses

the charges already present on it to generate more charges by

electrostatic induction. It does not rely on friction for its operation.

Consider that the machine is charged as in the schematic representation,

shown (with cylinders instead of disks) with each half of each disk with

one polarity, with boundaries at the neutralizing bars. Ignore the charge

collectors and the output circuit. The two neutralizer bars are shown

floating, but it makes no difference in the operation if they are

grounded. At top and bottom, the charges are opposite, and at the sides

equal. With any small initial charge unbalance, the machine will quickly

fall into this configuration. After this occurs, when a sector touches a

neutralizing brush charge is attracted to it, with polarity opposite to

the charges at the other disk, due to the influence of the electric field

generated by the surrounding sectors. Since there are several sectors

inducing charge in just one sector, more charge than is present in each of

the opposite sectors is attracted, provided that the disks and sectors are

at sufficiently small distance. The effect is that progressively larger

charges are attracted to the neutralized sectors as the disks turn, and

the voltages at all fixed sector positions grow exponentially. The buildup

stops when the charge density on the sector surfaces creates an electric

field intense enough to cause breakdown in the air around, usually just

before they reach the neutralizing brushes. The machine then operates

generating a constant current at the output circuit, with maximum voltage

limited by sparking through the path formed by a series of sectors and a

neutralizer rod, or by other losses in the structure due to insufficient

insulation. Note that the induction from the adjacent sectors in the same

disk is important. The sectors before a sector touching a neutralizer, and

also the charge collector assemblies and sectors at the sides of the

disks, generate intense electric field, and help in the induction. The

sectors ahead have their prejudicial effect reduced by the oppositely

charged sectors in the other disk. The machine is self-starting,

because there is always some natural imbalance in the charges. The use of

different metals in the sectors and in the neutralizing brushes helps the

startup process due to contact potential developed when different metals

touch.