Bennet's doubler is a simple electrostatic device where three insulated plates are used for charge multiplication. It can be built for manual operation, as originally described in 1787, or in a variety of automated forms, as the rotating versions designed by Nicholson and Bohnenberger, and the back-and-forth versions designed by Bohnenberger. In all these forms, two plates and one or more contacts move. A version of Bennet's doubler where only two plates move, and all the connections are made by fixed contacts, can be built as shown below. Plate A is fixed, and plates B and C are mounted on rotating insulating supports that rotate simultaneously, placing the plates B and C at the positions (a) and (b) as seen. In position (a), the charges in plates A and C, interconnected, are concentrated in plate A, while an inverted copy is generated on plate B, grounded. In position (b), An inverted copy of the charge in plate B is generated in plate C, grounded. With the return to position (a), the charges in plates A and B are doubled, with exactly the same operations of Bennet's doubler. Note that it's possible to use more than one set of plates B and C, as shown in (c). This leads to the idea of using disks with sectors, as in a Wimshurst machine, with the sectors providing sets of plates B and C. With several sectors, it's not even necessary to ensure synchronous movement.

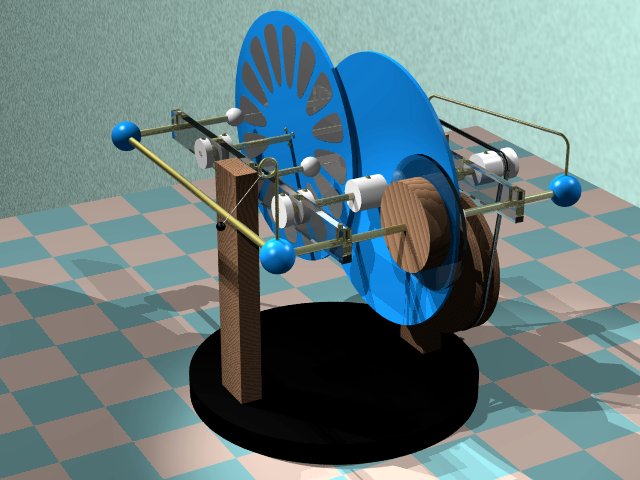

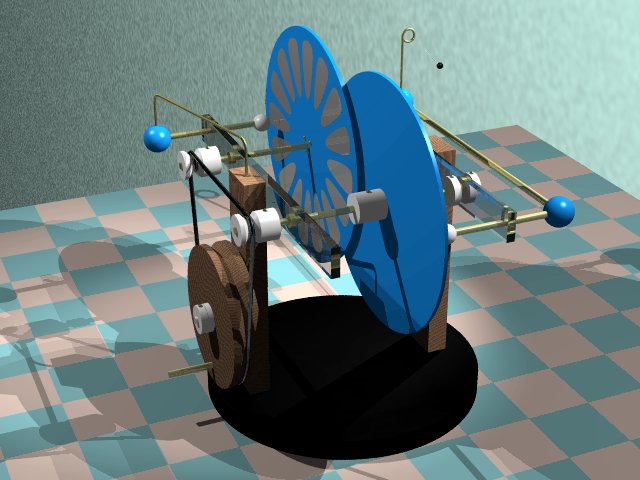

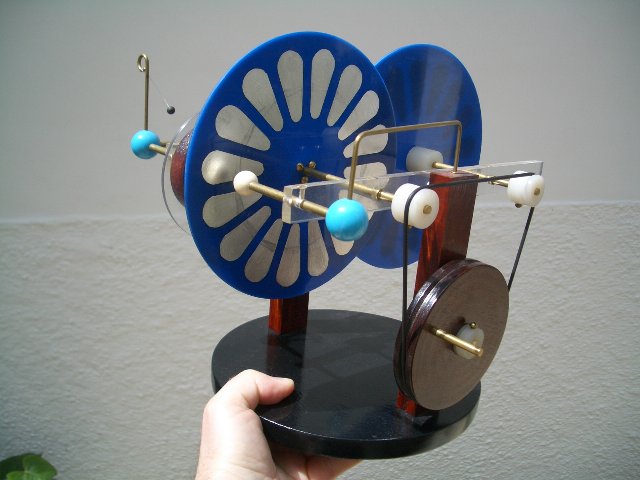

The picture below shows my plans for the construction of this machine. The two rotating disks are mounted side by side on two parallel axles, with an overlap, and moved by a crank and pulleys mechanism. The mechanical structure is similar to the one that I used in the "half Wimshurst machine". Plate A is a wood block permanently connected to a metal brush that touches the sectors C of the disk seen at left. A grounded brush (just connected to the wood structure) touches the same sectors C where the disks overlap.