The Holtz Electrostatic Influence Machine

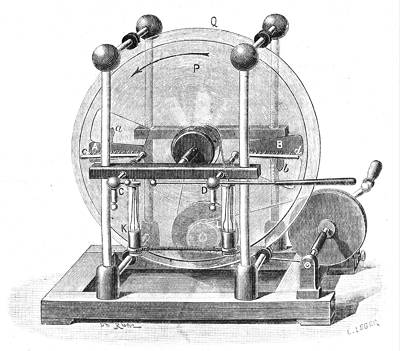

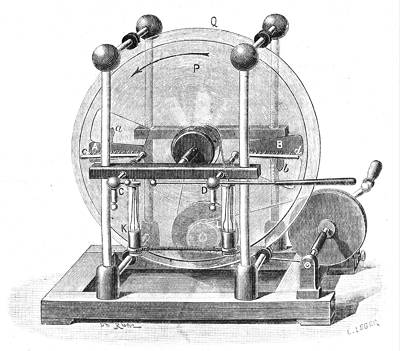

The machine known as the "Holtz machine of the first kind" was the first

really powerful influence machine to be developed. It was invented by

Wilhelm Holtz, in Germany, and first described in 1865 [p33].

In the basic form, it consists of a rotating

disk in front of a fixed disk slightly larger. The fixed disk has two

paper plates (inductors) glued to it at diametrically opposite positions,

with one or more points that project through wide windows in the disk,

ending close to the back surface of the rotating disk, that turns in a

direction opposite to that points. In the front side of the rotating disk,

opposite to the inductors in the fixed plate, close to the pointed side of

them, two charge collectors with series of points collect charge from the

front surface of the rotating disk, and are connected to the terminals of

the machine. The original machine was

described in [p33].

The machine known as the "Holtz machine of the first kind" was the first

really powerful influence machine to be developed. It was invented by

Wilhelm Holtz, in Germany, and first described in 1865 [p33].

In the basic form, it consists of a rotating

disk in front of a fixed disk slightly larger. The fixed disk has two

paper plates (inductors) glued to it at diametrically opposite positions,

with one or more points that project through wide windows in the disk,

ending close to the back surface of the rotating disk, that turns in a

direction opposite to that points. In the front side of the rotating disk,

opposite to the inductors in the fixed plate, close to the pointed side of

them, two charge collectors with series of points collect charge from the

front surface of the rotating disk, and are connected to the terminals of

the machine. The original machine was

described in [p33].

To see how it works, assume that the disk is charged with negative charge

at the frontal surface at the left side of the machine (schematic,

with cylinders instead of disks). When it passes in front of the points

connected to the left inductor, negative charges are repelled from the

disk's back surface to the inductor, where they become concentrated in

front of the adjacent charge collector. When the disk passes in front of

the left charge collector, the negative charges in the disk are repelled

by the negative charges in the inductor to the output circuit, and the

disk leaves the charge collector with positive charge. The process is

repeated with inverted polarities at the other side. The charges in the

inductors increase exponentially, and the output voltage increases too,

until sparks occur at the terminals, or corona and losses limit the

voltage increase.

The machine built in this way requires constant current flow through the

output circuit to work. It must be started with the terminals

short-circuited, and if the terminals are separated beyond the maximum

sparking distance, it loses excitation, and can stop or revert polarity.

Holtz introduced the use of a "neutralizing rod"

to minimize this problem. This rod is a wire terminated in combs similar

to the charge collectors, positioned across the front disk, that acts as

an additional load positioned at an angle after the charge collectors. The

inductors are lengthened to cover an angle of 60-90 degrees, in order to

be also opposite to the ends of the neutralizing rod. It has no effect

while the load is conducting enough current, but prevents the loss of

excitation if the terminals are put too far apart, turning the machine

operation more stable. The original Holtz machine

with neutralizer [ p45] (1869).

Periodic polarity reversals occur easily, due to charge accumulation in

the inner side of the fixed disk, opposite to the inductor plates. This

charge eventually dominates over the charge in the inductors, reverting

the induction effect. As there are no brushes or metallic sectors, the

machine requires external excitation to start. It is enough to deposit

some charge in one of the inductor plates. The Holtz machine is similar to

the (more recent) Voss machine, but it doesn't

have sectors in the rotating disk and it's inductor plates collect charge

from the back of the rotating disk.

This machine had a fame of being difficult to start in humid weather, but

was considered one of the most powerful influence machines. Sparks with up

to 3/4 of the disk diameter were reported. Multiple

Holtz-type machines (This is the Holtz-Wimshurst machine [4]) were

extensively used as high voltage sources in early X-ray machines, due to

the high current output.

The Holtz machine can also be built with more than two inductor/collector

assemblies. A version with four inductors, built

by C. T. & J. N. Chester, that would produce twice more current at the

expense of some voltage, appears in [5]. The

picture is probably from [p105] (the

interconnection of the charge collectors is wrong. In this way the output

is short-circuited). It could be connected in several ways, including this [p127]

strange way with three charge collectors connected to one output and one

to the other. A similar machine [p125]

with the classical structure of the first publications by Holtz, that

could be connected in several ways, and a

version patented by the instrument builder

E. Ritchie [p128]. The idea of splitting the

fixed disk in several sections appears to

be due to H. Morton [p126]. This machine

(another picture, and see others here),

incomplete with the inductors and some connections missing, is another

implementation, as shown in this drawing

attributed to Elihu Thomson [67].

The Holtz machine of the second kind

This machine [p41]

(1867) consists of two parallel disks that rotate in opposite directions

at short distance, and four charge collector combs mounted in insulating

supports, two at opposite sides of the diameter of one disk, and two at

opposite sides of the perpendicular diameter of the other disk. The output

is taken between two separate sets of adjacent interconnected combs, as

shown. The machine can be seen as a basic Holtz machine where the plate

with inductors was replaced by another rotating disk. One disk serves as

inductor to the other, and vice-versa. The two outputs are combined to

double the output current. It is also equivalent to a Bonetti

machine (sectorless Wimshurst) where the charge collectors are removed and

the output taken in the middle of the neutralizer bars. It works as long

as there are sparks flowing, or a capacitor (Leyden jar) is being charged

between the terminals. In the original version

[24][p41], it had a fifth comb, later abandoned [p47]. Holtz experimented

also with a variation [p45]

(1869) of this design that is practically the Bonetti machine with output

taken at the front disk only (what gives to Holtz some priority in the

invention of that machine). The machine can have neutralizers too, to

allow operation with the output circuit open. In this case it's equivalent

to the Schaffers system (1885) for the Wimshurst

machine.

Many researchers studied the Holtz machines and variations. One of them

was Bleekrode [p95], that described experiments

with machines made with ebonite disks instead of glass disks in 1875.

Holtz himself wrote a long review paper in 1876 [p94].

My Holtz machine - construction

In June 1997, I finished the construction of a Holtz

machine. It uses two white acrylic disks with 31 cm and 27.5 cm of

diameter. The support structure consists of a base made of wood bars, four

insulating supports made with 1.5 cm PVC tubes, acrylic bars supporting

the axle and the charge collectors, and brass bars insulated by plastic

tubes supporting the fixed disk. Wood pieces with various shapes and some

screws interconnect and fix these parts.

The design is similar to the one of most classic machines, but using

modern materials. The rotating disk is mounted in a nylon boss, and is

turned by a double pulley system connected to a crank, with a overall 10:1

turns ratio. The boss and the middle pulley are mounted on ball bearings.

The cords turning the pulleys are large rubber o-rings. The charge

collectors are made with serrated thick aluminum foil fixed in slits in

nylon rounded cylinders with a central aluminum rod. Brass bars insulated

by plastic tubes connect the collectors to the terminals, that can be

turned in (complicated and not very good) joints made of nylon and PVC.

The terminals are aluminum balls with 2.5 cm of diameter fixed to brass

bars that end in PVC tube handles. The neutralizer combs are identical to

the charge collectors, and are fixed to brass bars that are fixed to a

central aluminum piece in the axle. The neutralizer can be rotated to any

angle. The inductors are made of drawing paper, covering an angle of 60

degrees.

Operation of my Holtz machine

The machine is rather sensitive to humidity (as any machine without

metallic sectors), as has to be warmed with a hair dryer for some time

before operation in humid weather. To start the machine, it is enough to

apply some charge to one of the inductors. I do this by connecting a

sectored machine to one inductor, or by discharging a Leyden jar in one.

After the first start, it is easy to start it again while it retains some

charge by simply touching one of the inductors with the machine turning,

or moving the neutralizing rod to another position.

Without the neutralizer bar, the machine only works reliably when

connected to rather large Leyden jars (200 pF). With small load

capacitances it can start, but soon loses excitation. It enters a curious

cycle of rapid polarity reversals at about each 10 turns of the disk, and

reaches only moderately high voltage (3 cm sparks). Maybe I should have

tried smaller inductor plates, as the ones that I installed were larger

than the ones seen in pictures of classic machines. With the neutralizer

bar and longer inductors, it works even without capacitive load, takes

longer to revert polarity, and reaches higher voltages (8 cm sparks, with

a 9 mm ball glued to the positive terminal, separated by a short plastic

tube).

The machine works even with the output terminals short circuited, and

produces a rather high output current of about 37 uA. The voltage doesn't

increase more probably due to the accumulation of charge in the inner side

of the fixed disk. The collection of charge by the inductors generates

opposite charges exactly as the rotating disk passes under the inductors,

and part of this charge is attracted to the fixed disk. I am still

investigating some way to minimize this problem. The insulation of the

machine allows much higher voltages than I am obtaining. (But a spark

length of 1/4 of the disk diameter is not so bad. It is better than what

my Wimshurst machine produces, and the current

output is higher than in my Bonetti machine,

that uses larger disks.)

The periodical voltage reversals produce a beautiful display in the dark,

with many sparks covering the disks as the charges rearrange. I tried also

the use of metallic inductors, made of aluminum foil. They work as well as

the paper inductors, but in the dark it is apparent that the losses are

higher. The periodical polarity reversals occur at shorter intervals, and

the maximum spark length is somewhat reduced. My final design used paper

inductors with a metal strip under them. This turned the machine less

sensitive to humidity conditions and made it work more consistently.

The machine was built with the neutralizing bar insulated, and so can be

operated with one terminal grounded. With this the voltage at the other

terminal reaches almost twice the normal voltage. In this condition, the

light display in the dark is greatly enhanced, and (for some reason) the

maximum spark length is somewhat increased when the negative terminal is

grounded.

A different configuration:

By looking at the schematic diagram of the Holtz machine, it can be

observed that at the upper and lower quadrants, the rotating disk has

charges of equal polarities at both sides. If the neutralizer is rotated

so that it is above these areas, significant current flows through it. In

the other hand, the polarities of the charges in opposite sides of the

rotating disk are opposite when it passes in front of the charge

collectors, what reduces the induction effect.

Observing this, I rotated the fixed disk so that the inductors were at

the top and bottom quadrants, with the neutralizer in a vertical position,

acting as a short-circuit load, and the output being taken where the

voltage is maximum. This resulted in significantly higher voltages being

generated (11 cm sparks), although with smaller maximum current (16 uA).

I have found little reference to this possibility in old references,

although the design of the classical machines allowed this modification.

There is a hint about this idea in a paper by Holtz [p42]

(1867), and also brief comments in [27]. This

could be the reason for the holes in the fixed disk for the collectors

that feed the inductors, instead of simpler cuts in the sides of the

disks. With the fixed disk having a continuous border, it is simple to

rotate it to any position over its supports. The modification works better

if the inductors cover a small angle. I didn't try less than 60 degrees.

In January 2001, I modified the frontal bar that holds the charge

collectors and the axle, that had cracked. I fixed the conductors leading

to the terminals with screws (I replaced all the fixation screws for the

bars and the axle by similar screws made from 3/16" threaded rods and wood

balls), and modified the union between the conductors and the terminals by

wood balls, that have brass inserts where slotted plugs cut at the end of

the conductor bars can rotate. Front. Back.

See also the Wehrsen machine, that is an

improved version with embedded sectors in the rotating disk and a startup

system.

Last update: 29 December 2017

Created and maintained by Antonio Carlos M. de

Queiroz

Return to Electrostatic Machines

The machine known as the "Holtz machine of the first kind" was the first

really powerful influence machine to be developed. It was invented by

Wilhelm Holtz, in Germany, and first described in 1865 [p33].

In the basic form, it consists of a rotating

disk in front of a fixed disk slightly larger. The fixed disk has two

paper plates (inductors) glued to it at diametrically opposite positions,

with one or more points that project through wide windows in the disk,

ending close to the back surface of the rotating disk, that turns in a

direction opposite to that points. In the front side of the rotating disk,

opposite to the inductors in the fixed plate, close to the pointed side of

them, two charge collectors with series of points collect charge from the

front surface of the rotating disk, and are connected to the terminals of

the machine. The original machine was

described in [p33].

The machine known as the "Holtz machine of the first kind" was the first

really powerful influence machine to be developed. It was invented by

Wilhelm Holtz, in Germany, and first described in 1865 [p33].

In the basic form, it consists of a rotating

disk in front of a fixed disk slightly larger. The fixed disk has two

paper plates (inductors) glued to it at diametrically opposite positions,

with one or more points that project through wide windows in the disk,

ending close to the back surface of the rotating disk, that turns in a

direction opposite to that points. In the front side of the rotating disk,

opposite to the inductors in the fixed plate, close to the pointed side of

them, two charge collectors with series of points collect charge from the

front surface of the rotating disk, and are connected to the terminals of

the machine. The original machine was

described in [p33].