It comprises three insulated brass

plates with 15 cm of diameter, with a mechanism to move the central

plate back and forth, and three diodes, built as series associations of

5 1N4007 diodes mounted on acrylic plates for high insulation. This

is the schematic diagram of the machine.

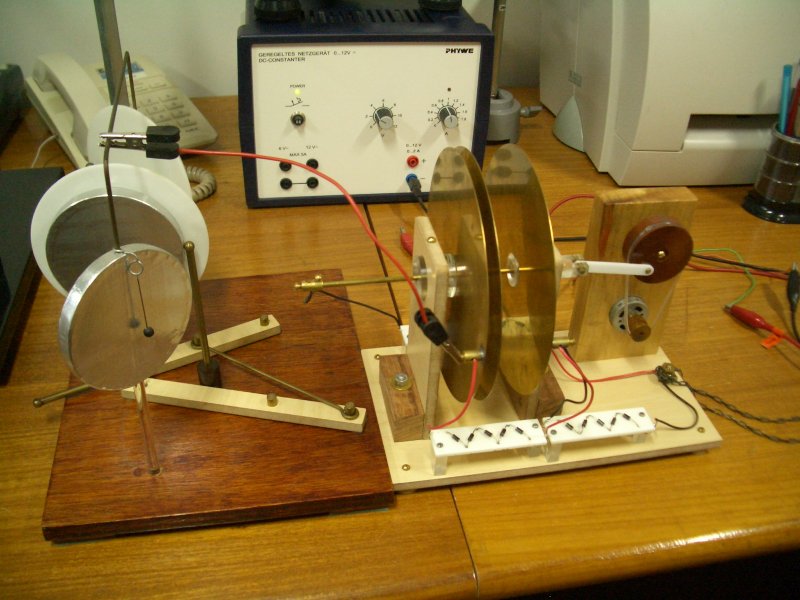

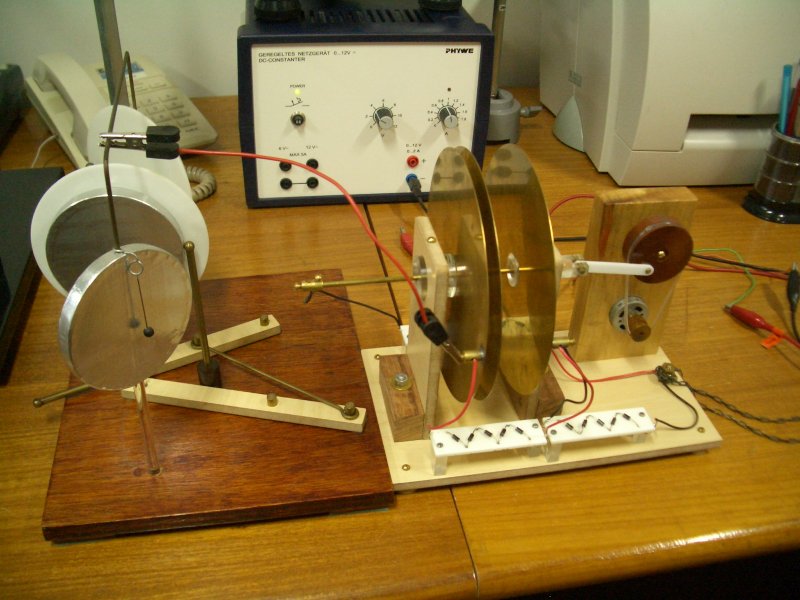

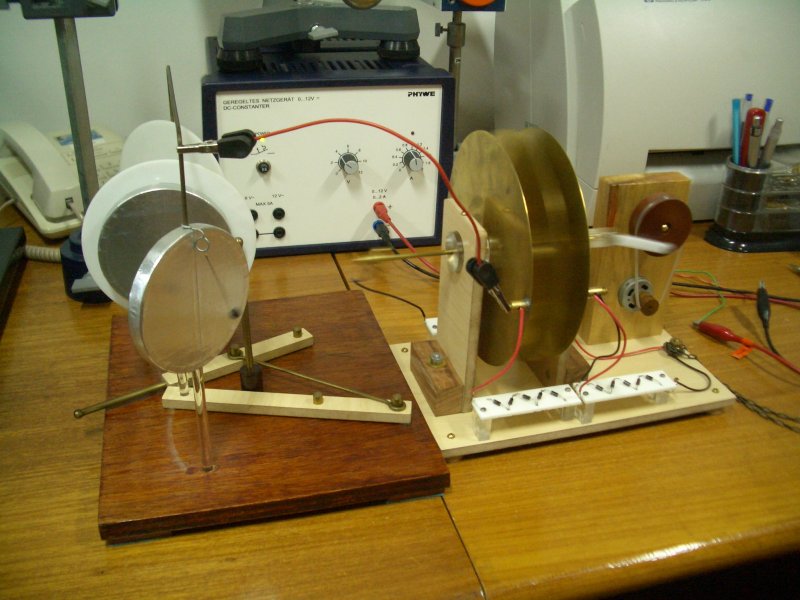

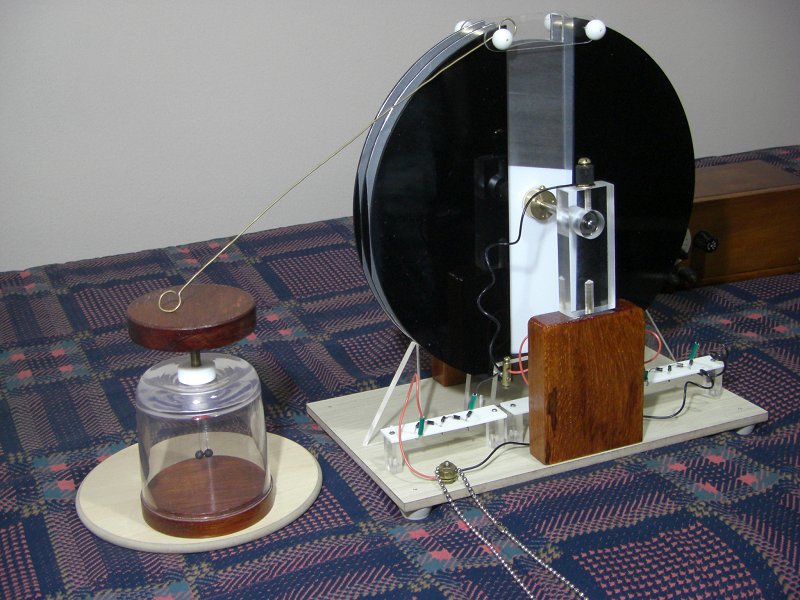

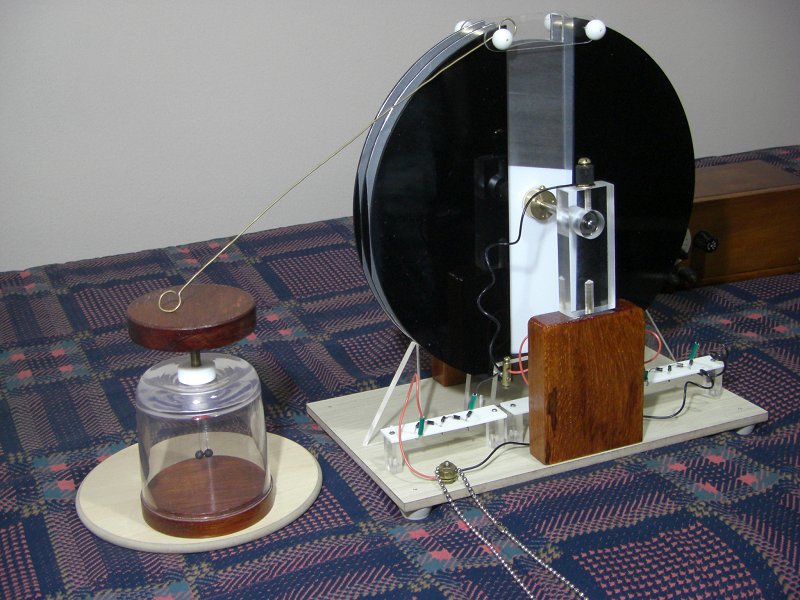

The machine is not self-exciting, but has to be charged by applying an initial positive charge to the leftmost plate, that is also the output terminal of the machine. This can be obtained by connecting the machine to a small electrostatic machine, or just by approximating a charged object from the plate. In the setup below, it is charged by a Wilson machine:

After startup, the machine increases the initial charge until sparking

occur between the plates, or leakage trough the diodes clamps the

voltage. The maximum voltage obtained is of about 6500 V. The central

plate oscillates at about 5 cycles per second.

The machine is not self-exciting, but has to be charged by applying an initial positive charge to the leftmost plate, that is also the output terminal of the machine. This can be obtained by connecting the machine to a small electrostatic machine, or just by approximating a charged object from the plate. In the setup below, it is charged by a Wilson machine:

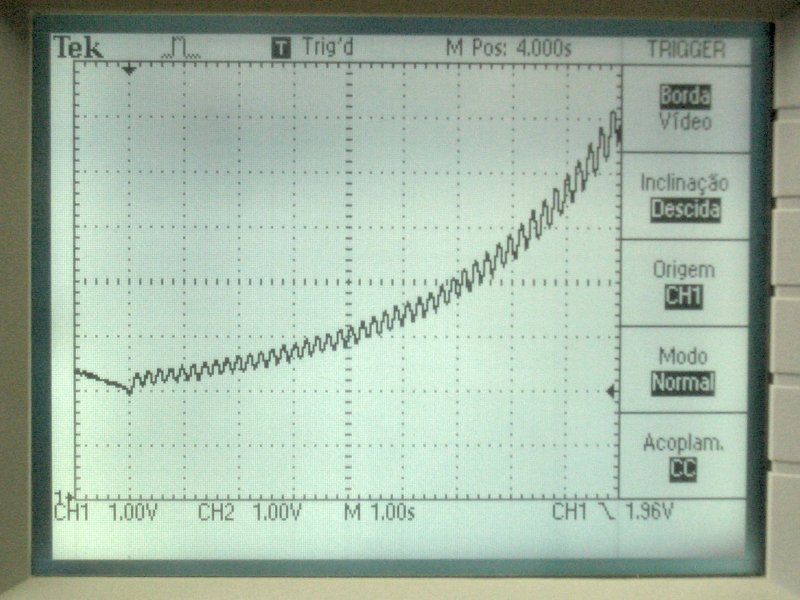

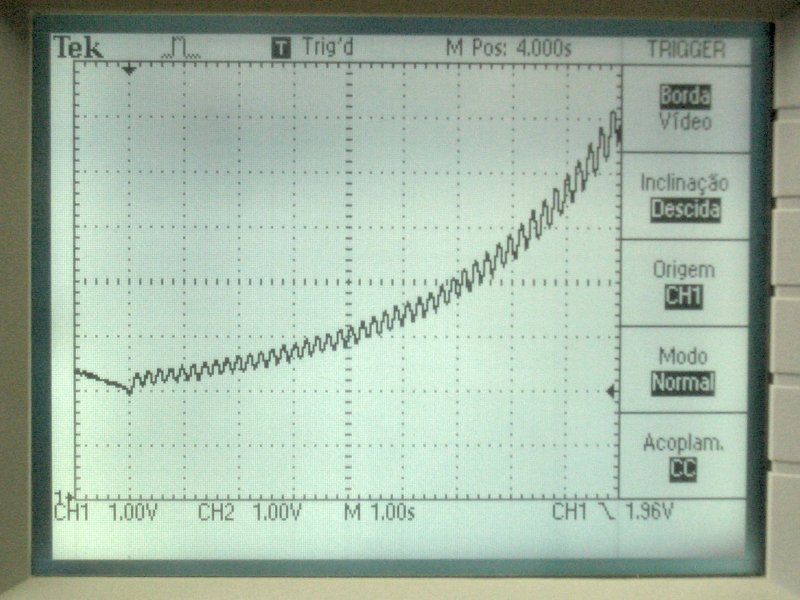

The output voltage can be measured

with an electrostatic voltmeter. A Phywe electrometer was used,

connected to an oscilloscope. The picture below shows the charging

waveform. The machine has to be charged to at least 100 V to start,

to compensate for leakage and drop in the diodes, and because at low

voltage the nonlinear diode capacitances, higher at low voltage,

turn the circuit stable. In the test setup, it was allowed to

discharge to 200 V, and the vibration was started. The bandwidth of

the electrometer is too low to show the actual waveform. The peaks

are actually higher than shown. The vertical scale is 100 V/div.

This device is being studied for

application as electrostatic energy harvester. A version can be

possibly built by MEMS (microelectromechanical) techniques in an

integrated circuit and used to harvest energy from ambient

vibration.

A video of the machine in operation.

Another video, this time excited by a Bohnenberger machine and powering some demonstration devices at ~6 kV.

A self-starting version

In October 2010 I completed a new version of the same device, designed to have enough capacitance between the plates to be unstable even when completely discharged. The machine was built as a rotating machine, with two rotating central plates moving between two fixed groups of three plates. The plates were made of acrylic, covered by aluminum tape. The fixed plates are connected to terminals below, and the rotating plates to the insulated central axle, that has a terminal in contact with one of the ball bearings that support it. A small motor turns the machine. The diodes are as in the previous version.

The machine worked as expected, never failing to start without previous excitation. The five diodes in series used don't appear to be a problem for the self-excitation. It reaches about 6 kV, limited by the maximum reverse voltage of the diodes and by internal sparking.

A video of the machine in operation, connected to an electroscope.

An improved version of this machine was demonstrated in the 2011 IEEE ISCAS conference, in Rio de Janeiro, driving a DC-DC converter to produce low-voltage output. Video of the demonstration.

The machine also works with a single variable capacitor. In this picture, the variable capacitor at the right side is disconnected and replaced by a 50 pF Leyden jar capacitor. The machine works in the same way, with a slightly reduced output. Video.

Third version

In September 2013 I built a new machine, with greater capacitance variation (30-330 pF), using a symmetrical double variable capacitor to avoid the counterweight of the previous machine. It can also turn faster and makes two capacitance variation cycles per turn. The two capacitors are formed when the rotor is at 45 degrees with the base, each formed by 6 pairs of 7 x 7 cm aluminum plates and 5 rotating pairs of plates with similar shape. The distances between the plates is ~2.5 mm. The plates and rotor are mounted on threaded rods with nuts, between two HDPE plates. A small DC motor turns the machine. The three diodes are high-voltage microwave oven diodes, that have very low leakage and capacitance, and are very robust. The machine self-excites easily even when turned by hand, and reaches 3500 V before sparking between the plates.

Created: 22/11/2009

Last update: 20/10/2013

By Antonio Carlos M. de Queiroz

Return to Electrostatic Machines.

A video of the machine in operation.

Another video, this time excited by a Bohnenberger machine and powering some demonstration devices at ~6 kV.

A self-starting version

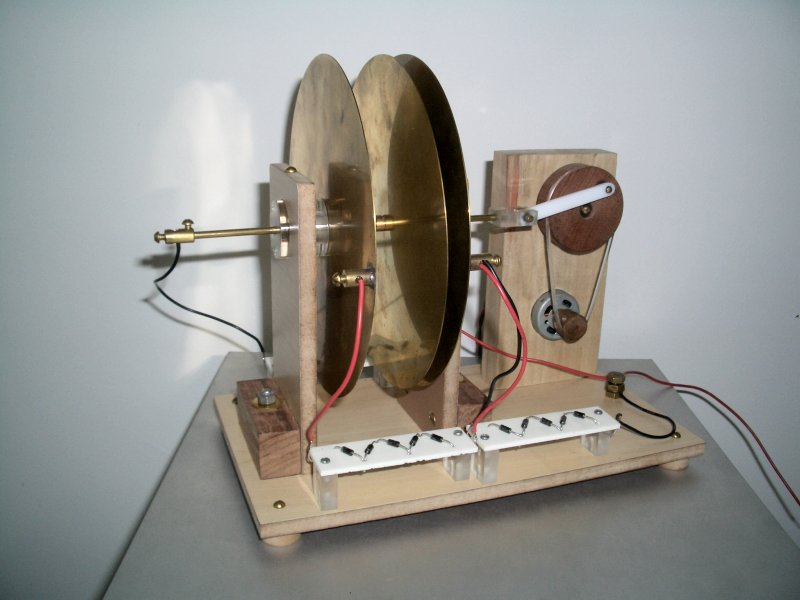

In October 2010 I completed a new version of the same device, designed to have enough capacitance between the plates to be unstable even when completely discharged. The machine was built as a rotating machine, with two rotating central plates moving between two fixed groups of three plates. The plates were made of acrylic, covered by aluminum tape. The fixed plates are connected to terminals below, and the rotating plates to the insulated central axle, that has a terminal in contact with one of the ball bearings that support it. A small motor turns the machine. The diodes are as in the previous version.

The machine worked as expected, never failing to start without previous excitation. The five diodes in series used don't appear to be a problem for the self-excitation. It reaches about 6 kV, limited by the maximum reverse voltage of the diodes and by internal sparking.

A video of the machine in operation, connected to an electroscope.

An improved version of this machine was demonstrated in the 2011 IEEE ISCAS conference, in Rio de Janeiro, driving a DC-DC converter to produce low-voltage output. Video of the demonstration.

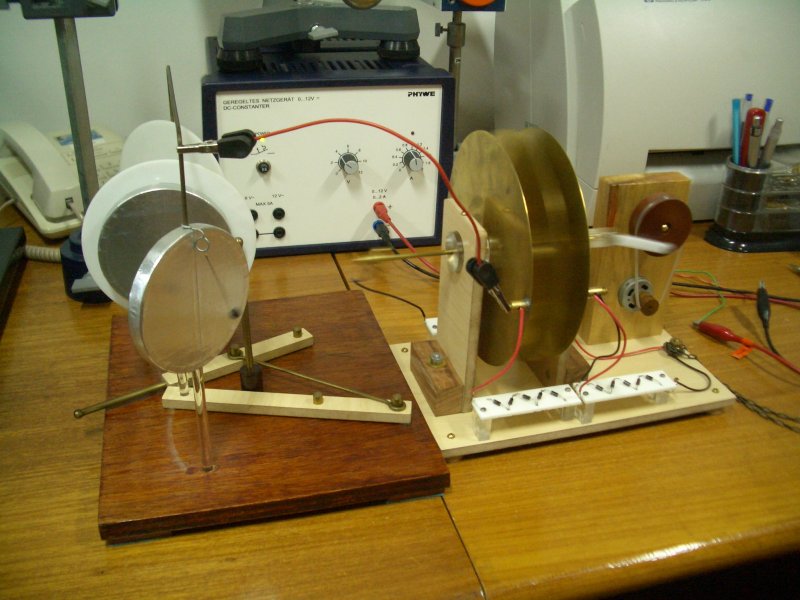

The machine also works with a single variable capacitor. In this picture, the variable capacitor at the right side is disconnected and replaced by a 50 pF Leyden jar capacitor. The machine works in the same way, with a slightly reduced output. Video.

Third version

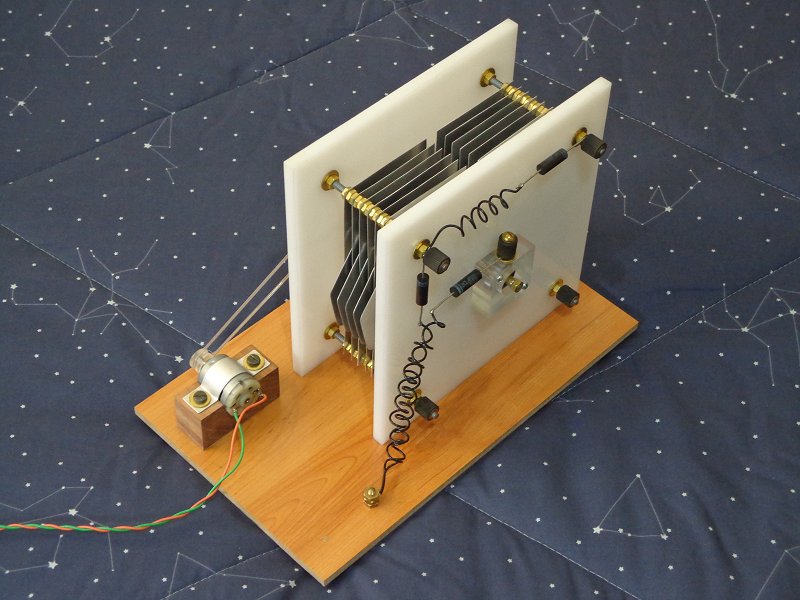

In September 2013 I built a new machine, with greater capacitance variation (30-330 pF), using a symmetrical double variable capacitor to avoid the counterweight of the previous machine. It can also turn faster and makes two capacitance variation cycles per turn. The two capacitors are formed when the rotor is at 45 degrees with the base, each formed by 6 pairs of 7 x 7 cm aluminum plates and 5 rotating pairs of plates with similar shape. The distances between the plates is ~2.5 mm. The plates and rotor are mounted on threaded rods with nuts, between two HDPE plates. A small DC motor turns the machine. The three diodes are high-voltage microwave oven diodes, that have very low leakage and capacitance, and are very robust. The machine self-excites easily even when turned by hand, and reaches 3500 V before sparking between the plates.

Created: 22/11/2009

Last update: 20/10/2013

By Antonio Carlos M. de Queiroz

Return to Electrostatic Machines.